Cr3C2-NiCr for high-temperature anti-oxidation and wear resistance

Short Description:

Description

Cr3C2-NiCr is a highly effective composite material widely used in industries that require high temperature and wear resistance. The material is composed of chromium carbide (Cr3C2) and nickel-chromium (NiCr) alloy, making it an ideal solution for applications where high-temperature oxidation and wear resistance are required.

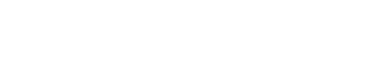

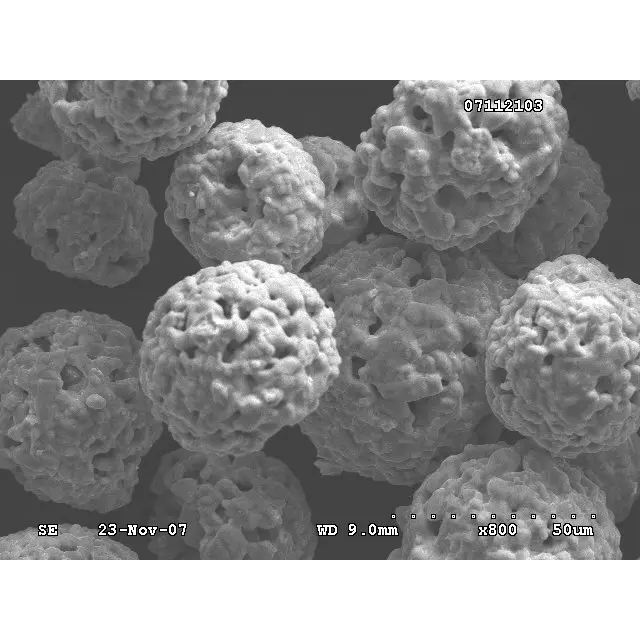

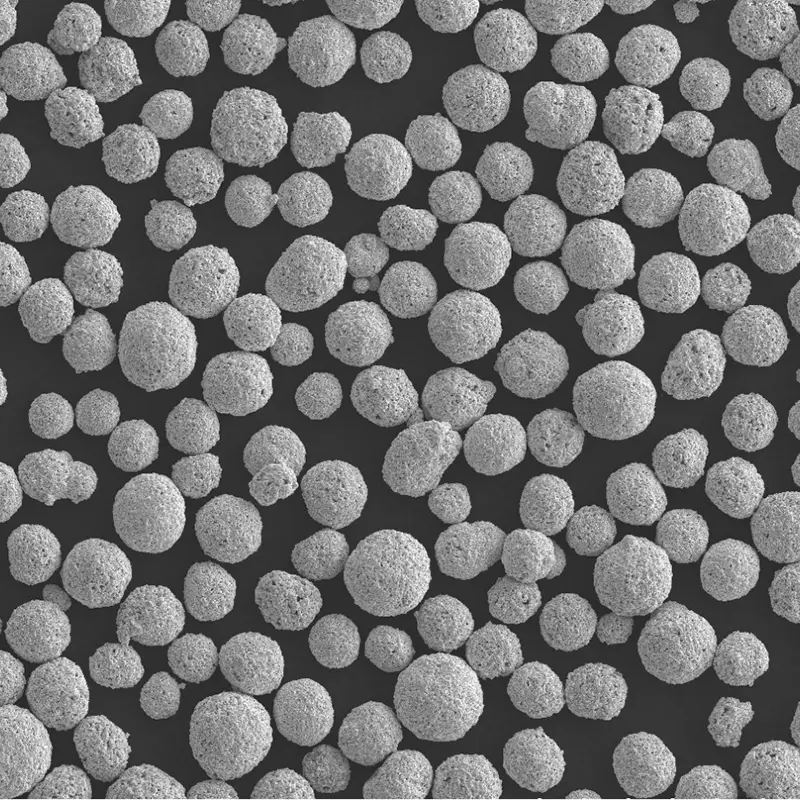

The KF-70, KF-69, and KF-71 grades of Cr3C2-NiCr are known for their superior performance and durability under high-temperature conditions. The particle size of each grade ranges from 15-45 μm and 20-53 μm, and they are agglomerated and sintered to ensure maximum strength.

KF-70 Cr3C2-25NiCr offers excellent resistance to oxidation and wear at 815 ℃. It is highly recommended for applications in high-temperature environments that require long-lasting performance, such as turbine blades and gas turbine engines.

KF-69 Cr3C2-20NiCr is another highly effective grade that offers superior resistance to oxidation and wear at 815 ℃. It is ideal for use in a wide range of high-temperature applications, including chemical processing and heat treatment.

KF-71 Cr3C2-30NiCr is a top-performing grade that offers even better toughness than other grades in the Cr3C2-NiCr family. It is highly recommended for applications where durability and toughness are crucial, such as oil and gas drilling tools, high-temperature molds, and die casting tools.

In summary, the Cr3C2-NiCr family of products, including KF-70, KF-69, and KF-71, is an ideal solution for applications that require high-temperature oxidation and wear resistance. These products offer superior durability and toughness under high-temperature conditions, making them ideal for use in industries such as aerospace, automotive, and energy. With their excellent performance and reliability, Cr3C2-NiCr products are an excellent choice for anyone looking for a high-quality, long-lasting solution for high-temperature applications.

Similar Products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-70F | Cr3C2-25NiCr | 584 | 72027205 | CRC-3001375 | 5129 | |

| KF-69 | Cr3C2-20NiCr | 578 / 586 | 7101 / 7102 | CRC-351 | 8270 | |

| KF-71F | Cr3C2-30NiCr | 575 |

Specification

| Brand | Product Name | Particle Size (μm) | Chemistry (wt%) | Type | Apparent density | Flowability | Properties | Application | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Co | C | Fe | W | Cr | B | Si | Ni | ||||||||

| KF-65 | WC-10Co4Cr | 15-45, 10-38 | 9.5-10 | 5.3-5.6 | ≤0.8 | Bal. | 3.5-4.0 | Sinter&Crush | 5.5-6.5g/cm3 | ≤25 s/50g | APS,HVOF,HVAF | Alternative hard chromium plating; Petroleum, paper, general machinery | |||

| KF-65 | WC-10Co4Cr | 15-45,10-38,5-30 | 9.5-10 | 5.3-5.6 | ≤0.8 | Bal. | 3.5-4.0 | Agglomerated and sintered | 4.0-6.0 g/cm3 | ≤18 s/50g | APS,HVOF,HVAF | Alternative hard chromium plating; Petroleum, paper, general machinery | |||

| KF-65 | WC-10Co4Cr | 5-25,5-15 | 9.5-10 | 5.3-5.6 | ≤0.8 | Bal. | 3.5-4.0 | Agglomerated and sintered | 3.5-4.8 g/cm3 | Stable feeding to powder feeder | HVOF,HVAF | Alternative hard chromium plating;Smoother surface, less or free post machining; | |||

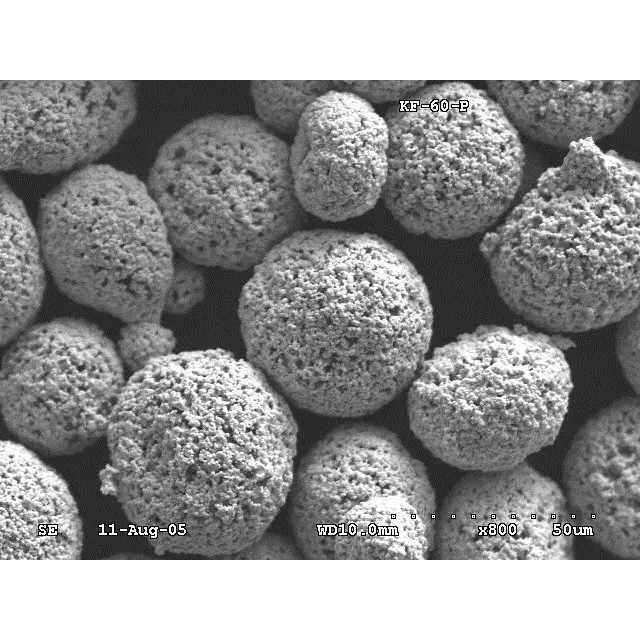

| KF-60 | WC-12Co | 15-45,10-63 | 10.5-12 | 4.9-5.4 | ≤0.8 | Bal. | Sinter&Crush | 5.5-6.5 g/cm3 | ≤25 s/50g | APS,HVOF | Wear resistance,Fretting wear resistance | ||||

| KF-60 | WC-12Co | 15-45,10-38,5-30 | 10.5-12 | 4.9-5.4 | ≤0.8 | Bal. | Agglomerated and sintered | 4.0-6.0 g/cm3 | ≤18 s/50g | APS,HVOF,HVAF | Wear resistance,Fretting wear resistance;general machinery | ||||

| KF-61 | WC-17Co | 15-45,10-38 | 15.5-17 | 4.5-5.1 | ≤0.8 | Bal. | Agglomerated and sintered | 3.5-5.5 g/cm3 | ≤25 s/50g | APS,HVOF,HVAF | Wear resistance,Fretting wear resistance,Better toughness; general machinery | ||||

| KF-62 | WC-25Co | 15-45,10-38 | 22-26 | 4.0-4.6 | ≤0.8 | Bal. | Agglomerated and sintered, Densification | 3.0-5.5 g/cm3 | ≤25 s/50g | APS, Detonation guns,cold spray | Fretting wear resistance,Better toughness | ||||

| KF-66 | WC-23%CrC-7Ni | 15-45,10-38 | 6.0-6.8 | ≤0.8 | Bal. | 16.5-20 | 5.5-7 | Agglomerated and sintered | 3.0-5.0 g/cm3 | ≤25 s/50g | APS,HVOF,HVAF | Alternative hard chromium plating;Used for low concentration acid/alkali environment at 200 ℃; Anti oxidation and wear resistance at 750 ℃ | |||

| KF-66 | 43WC-43%CrC-14Ni | 15-45,10-38 | 7.8-8.4 | ≤0.8 | Bal. | 35-38 | 12-14 | Agglomerated and sintered | 2.0-4.0 g/cm3 | ≤35 s/50g | APS,HVOF,HVAF | Alternative hard chromium plating Used for low concentration acid/alkali environment at 200 ℃ | |||

| KF-63 | WC-10Ni | 15-45,10-38 | 4.5-5.2 | ≤0.1 | Bal. | 8.5-10.5 | Agglomerated and sintered | 4.0-6.0 g/cm3 | ≤18 s/50g | APS,HVF,HVAF | Non magnetic wear resistant coating. Better corrosion resistance | ||||

| KF-70 | Cr3C2-25NiCr | 15-45, 20-53 | 9-11 | ≤1 | Bal. | 18-21.5 | Agglomerated and sintered | ≥2.3 g/cm3 | Stable feeding to powder feeder | APS,HVOF | Anti oxidation and wear resistance at 815 ℃ | ||||

| KF-69 | Cr3C2-20NiCr | 15-45, 20-53 | 9-11 | ≤1 | Bal. | 15-17.5 | Agglomerated and sintered | ≥2.3 g/cm3 | Stable feeding to powder feeder | APS,HVOF | Anti oxidation and wear resistance at 815 ℃ | ||||

| KF-71 | Cr3C2-30NiCr | 15-45, 20-53 | 9-11 | ≤1 | Bal. | 15-17.5 | Agglomerated and sintered | ≥2.3 g/cm3 | Stable feeding to powder feeder | APS,HVOF | Anti oxidation and wear resistance at 815 ℃. Better toughness | ||||

| KF-60 | WC-12Co (Low Carbon) | 15-45, 20-53 | 10.5-12 | 4.0-4.4 | ≤0.8 | Bal. | Agglomerated and sintered | 4.0-6.0 g/cm3 | ≤18 s/50g | HVOF,HVAF | Used for Zn bath rolls in Continuous Galvanizing Lines | ||||

| KF-68 | WC-30WB-10Co | 15-45,20-53,10-38 | 9-11 | 3.5-3.9 | Bal. | 1.4-1.7 | Agglomerated and sintered | 3.0-4.9 g/cm3 | ≤30 s/50g | HVOF,HVAF | Used for Zn bath rolls in Continuous Galvanizing Lines | ||||

| KF-68 | WC-30WB-5Co5Cr | 15-45,20-53,10-38 | 4-6 | 3.5-3.9 | Bal. | 4-6 | 1.4-1.7 | Agglomerated and sintered | 3.0-4.9 g/cm3 | ≤30 s/50g | HVOF,HVAF | Used for Zn bath rolls in Continuous Galvanizing Lines | |||

| KF-300E | 35%WC-NiCrBSi | 15-53,45-104 | 2.5-3.2 | 1.0-2.6 | 32-35 | 7.5-9 | 1.5-1.9 | 2.0-2.7 | Bal. | WC and NiCrBSi forming alloy | 4.0-4.9 g/cm3 | ≤16 s/50g | HVOF,PS | Alternative Blended type WC+Ni60;Higher material utilization,Lower energy consumption, lower thermal impact;Used for glass mold | |

| KF-300F | 50%WC-NiCrBSi | 15-53,45-104 | 3.2-4.3 | 0.8-2.0 | 45-48 | 5.8-7.2 | 1.0-1.7 | 1.5-2.4 | Bal. | WC and NiCrBSi forming alloy | 5.0-7 g/cm3 | ≤16 s/50g | HVOF,P | ||