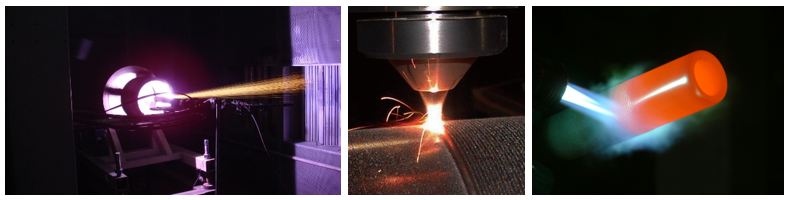

Thermal spraying is a cutting-edge technology that is transforming the surface coating industry. This process involves heating a material to its melting point and then propelling it onto a surface to form a coating. The technology has been used for decades in a variety of industries and has become increasingly popular due to its versatility, efficiency, and durability.

One of the biggest advantages of thermal spraying is its versatility. A wide range of materials can be used in the process, including metals, ceramics, polymers, and even biocompatible materials. This allows for the creation of functional and decorative coatings for a variety of products and applications. For example, thermal spraying can be used to improve the performance of airplane components by adding a layer of protective coating, or to enhance the appearance of jewelry by adding a decorative coating.

Another advantage of thermal spraying is its efficiency. The process can be performed quickly and easily, reducing production time and costs. Additionally, the coatings produced are extremely durable, withstanding harsh environments and maintaining their properties for extended periods of time. This makes thermal spraying an ideal solution for industries that require high-performance coatings, such as the aerospace and energy industries.

However, there are also some challenges associated with thermal spraying technology. The process requires specialized equipment and highly trained operators, and the cost of production can be relatively high. Additionally, there are environmental concerns related to the release of particulate matter during the spraying process.

Despite these challenges, the future of thermal spraying technology is bright. Research and development efforts are ongoing, and the field is advancing rapidly. For example, recent advances in automation and robotics have made thermal spraying more accessible and easier to use. Additionally, new materials are being developed specifically for use in thermal spraying, expanding the range of applications for the technology.

In conclusion, thermal spraying technology is revolutionizing the surface coating industry. Its versatility, efficiency, and durability make it a valuable tool for industries across the board. As the technology continues to evolve and advance, the possibilities for its applications are virtually limitless. From improving the performance of airplane components to enhancing the appearance of jewelry, thermal spraying is poised to play a major role in shaping the future of surface coatings.

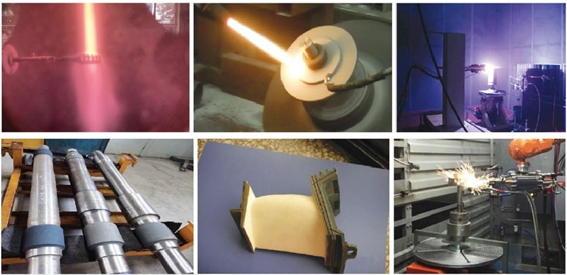

Applicable scenarios

Ferrous Metallurgy

In the iron and steel metallurgical industry, a large number of equipment parts operate under high, medium and low temperature heavy load or corrosive environment, and typical parts include bottom roller, sinking roller and so on. The service life of components is the focus of enterprises. The application of thermal spraying technology successfully improves the service life of these workpieces, improves the production efficiency and product quality of enterprises, and reduces the production cost of enterprises.

Petroleum and petrochemical industry

Thermal spraying technology has been recognized in solving the problems of anti-corrosion, wear resistance and wear reduction of important parts of core equipment in petroleum and chemical enterprises. Typical components include valve stem, screw, shaft, sleeve, hydraulic support and so on. At the same time, in view of the wear problem of petroleum and petrochemical parts, compared with chromium plating, thermal spraying technology has the advantages of environmental protection and prolonged service life, and its high cost performance makes it widely used in the protection of vulnerable parts.

Energy and electricity

In the energy and power industry, thermal spraying technology has been widely used. Typical components include steam turbines, gas turbines, tenons, blades and so on. Especially in the environment with special functional requirements such as high temperature resistance, corrosion resistance, wear resistance and sealing, this technology can prolong the service cycle of the workpiece, improve the life and work efficiency of the whole machine, reduce the operation and maintenance cost of the equipment, and bring considerable economic benefits to the enterprise.

New energy and semiconductor industries

Thermal spraying technology is being vigorously promoted in the new energy and semiconductor industries, especially the key and important parts of new energy vehicles, automobile batteries, semiconductor targets and silicone, which mainly solve the problems of wear resistance, corrosion resistance and insulation of important parts of core equipment of enterprises. This technology is helpful to improve the service life of key components, reduce the frequency of maintenance and replacement, meet the needs of working conditions, and bring rich economic benefits to enterprises.

Other Industries

Thermal spraying technology is also widely used in aviation industry, machinery manufacturing, light industry, transportation and many other fields. Its contribution to the development of national economy is indispensable.