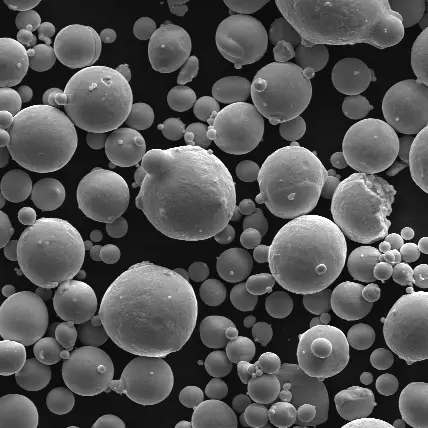

MCrAlY Alloy with high temperature resistance

Short Description:

Description

Brand: KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Type: Gas atomized

Powder Properties: Chemical Composition: MCrAlY (M = Fe, Ni, or Co) Particle Size: -45 +15 µm Purity: ≥ 99.5%

Application: MCrAlY Alloy powders are widely used in high-temperature applications due to their unique properties. They are commonly used as bond coats in metallurgical rolls, hot dip sink rolls, and heat treatment furnace rolls. Additionally, they are used in the aerospace industry for manufacturing gas turbine components, heat shields, and aero engine blades.

Characteristics Of MCrAlY Alloy

1.High Temperature Resistance: MCrAlY Alloy powders exhibit excellent resistance to high temperatures. This property makes them ideal for use in high-temperature applications such as gas turbines, heat treatment furnaces, and metallurgical rolls.

2.Antioxidant Properties: MCrAlY Alloy powders are highly resistant to oxidation at high temperatures, making them ideal for use in harsh environments where oxidation can occur, such as in gas turbines and heat shields.

3.Hot Corrosion Resistance: MCrAlY Alloy powders exhibit excellent resistance to hot corrosion, making them ideal for use in applications where the material is exposed to corrosive environments at high temperatures.

4.Thermal Barrier Substrate: MCrAlY Alloy powders are often used as thermal barrier substrates due to their excellent thermal conductivity and thermal expansion properties. They are used in conjunction with ceramic coatings to protect the underlying material from high-temperature environments.

Overall, MCrAlY Alloy powders are versatile materials that exhibit excellent high-temperature properties, making them ideal for use in a variety of applications across different industries. Their unique characteristics, including high-temperature resistance, antioxidant properties, hot corrosion resistance, and thermal barrier substrate properties, make them a popular choice for high-temperature applications.

Similar Products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-301 | ||||||

| KF-308 | NiCrAlY | 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | CoCrAlSiY | |||||

| KF-337 | CoNiCrAlY | 9954 | ||||

| KF-339 | CoCrAlYTaSiC |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | •APS, HVOF, detonation-gun, spherical •High temperature bond coats |

|||||||||||

| KF-308 | Nickel Chromium Aluminum Yttrium Alloy | 25 | 11 | 1 | Bal. | HRC 20-30 | ≤ 950ºC | •Metallurgical roll, hot dip sink roll, heat treatment furnace roll. •Aero engine blades, gas turbine, heat shield |

||||

| KF-309 | Nickel Cobalt Chromium Aluminum Yttrium Alloy | 25 | 6 | 0.5 | 22 | Bal. | HRC 20-30 | ≤ 950ºC | •High temperature resistance, antioxidant. •Hot corrosion resistance. •Thermal barrier substrate |

|||

| KF-336 | Cobalt Chromium Aluminum Silicon Yttrium Alloy | 29 | 7 | 0.5 | 3 | Bal. | HRC 20-30 | ≤ 1000ºC | •High temperature resistance, antioxidant. •Hot corrosion resistance, substrate |

|||

| KF-337 | Cobalt Chromium Aluminum Yttrium Alloy | 23 | 6 | 0.4 | Bal. | 30 | HRC 20-30 | ≤ 1050ºC | •High temperature resistance, antioxidant. •Hot corrosion resistance, thermal barrier substrate |

|||

| KF-339 | Cobalt Chromium Aluminum Yttrium Alloy | 24 | 7.5 | 0.8 | 10 | 0.8 | 2 | Bal. | ≤ 1100ºC | •APS, HVOF, detonation-gun, spherical •Metallurgical roll, high temperature annealing furnace roll. •Aero engine rotor blades, guide blades and gas turbine blades |

||