Iron Base Alloy for the working layer

Short Description:

Description

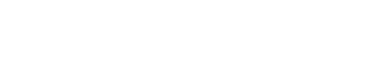

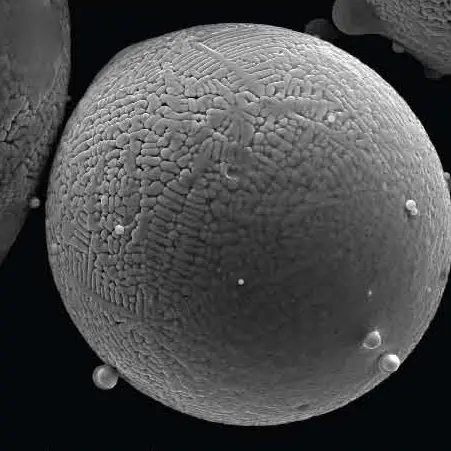

KF-JG-2 is used for the working layer of the blades, nozzles, wear rings, hydraulic rods, etc. KF-JG-3 has good sphericity, low oxygen content, high hardness, good toughness and outstanding crack resistance. It can be used for the repair and protection of various shafts, valves and rollers with corrosion resistance, high hardness and high wear resistance requirements.

Similar Products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-310 | FeCrBSi | |||||

| KF-311 | FeCrBSiNi | |||||

| KF-316L | Stainless Steel Alloy | 377 | 411003 | FE1011236 | 96 | |

| KF-JG-2 | FeCrNiMo Austenitic Proprietary | |||||

| KF-JG-3 | FeCrNiMo Martensitic Proprietary | |||||

| KF-Fe901 | FeCrBSiNi | |||||

| KF-Fe62 | FeCrBSiNi | |||||

| KF-Fe35 | FeCrBSiNi | |||||

| KF-Fe40 | FeCrBSiNi | |||||

| KF-D507 | FeCrBSiNi | |||||

| KF-D507Mo | FeCrBSiNi | |||||

| KF-D547Mo | FeCrBSiNi | |||||

| KF-D577 | FeCrBSiNi |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | B | Si | Ni | W | Mo | Mn | Fe | |||||

| KF-310 | FeCrBSi | 15 | 1 | 1 | Bal. | HRC 25 | ≤ 600ºC | •PTA, HVOF, laser cladding, spherical •Restore workpiece size, Paper-making dryer |

|||||

| KF-311 | FeCrBSiNi | 15 | 1 | 1 | 1 | Bal. | HRC 25 | ≤ 600ºC | •PTA, HVOF, laser cladding, spherical •Restore workpiece size •Better toughness and lower tendency to crack |

||||

| KF-316L | Stainless Steel Alloy | 17 | 1 | 12 | 2.4 | 0.1 | Bal. | HRC 25 | ≤ 540ºC | •PTA, HVOF, spherical •Turbine blades, nozzles, grinding rings, flow passage parts of pump, diesel engine cylinder •Good corrosion resistance |

|||

| KF-JG-2 | FeCrNiMo Austenitic Proprietary | <0.08 | 17 | <1.5 | 10 | 2-4 | HRB 100 | ≤ 540ºC | •Laser cladding, spherical •Turbine blades, nozzles, grinding rings,Wear resistant and corrosion-resistant parts •HRC30 |

||||

| KF-JG-3 | FeCrNiMo Martensitic Proprietary | Proprietary | HRC 54-58 | ≤ 540ºC | •Laser cladding, spherical •Mill liner, hydraulic prop, compressor blade, wear plate, wear belt, chain socket |

||||||||

| KF-Fe901 | Iron Base Alloy | 13 | 1.6 | 1.2 | 0.8 | Bal. | HRC 50 | ≤ 540ºC | •Laser cladding •Wear resistant coatings |

||||

| KF-Fe62 | Iron Base Alloy | 5 | 43 | 1.8 | 1 | Bal. | HRC 62-67 | ≤ 540ºC | •PTA •Oil drilling pipe joints •Turbine blades |

||||

| KF-Fe35 | Iron Base Alloy | 21 | 1.5 | 3.5 | Bal. | HRC 33-37 | ≤ 540ºC | •Medium pressure valves, heatproof rollers | |||||

| KF-Fe40 | Iron Base Alloy | 21 | 1.7 | 3.5 | Bal. | HRC 37-43 | ≤ 450ºC | •Better cooperation with Fe33-37, valve sealing surface | |||||

| KF-D507 | Iron Base Alloy | 13 | Bal. | HRC 30-35 | ≤ 450ºC | •Carbon steel, alloy steel, medium temperature and high pressure valves | |||||||

| KF-D507Mo | Iron Base Alloy | 2.5 | 13 | 6 | 2 | 2.5 | Bal. | HRC 35-40 | ≤ 450ºC | •Medium temperature and high pressure valves | |||

| KF-D547Mo | Iron Base Alloy | 13 | 5 | 10 | 5 | Bal. | HRC 35-40 | ≤ 450ºC | •High temperature and high pressure valves | ||||

| KF-D577 | Iron Base Alloy | 13 | 2 | 6 | 13 | Bal. | HRC 28 | ≤ 450ºC | •High temperature and high pressure valves | ||||